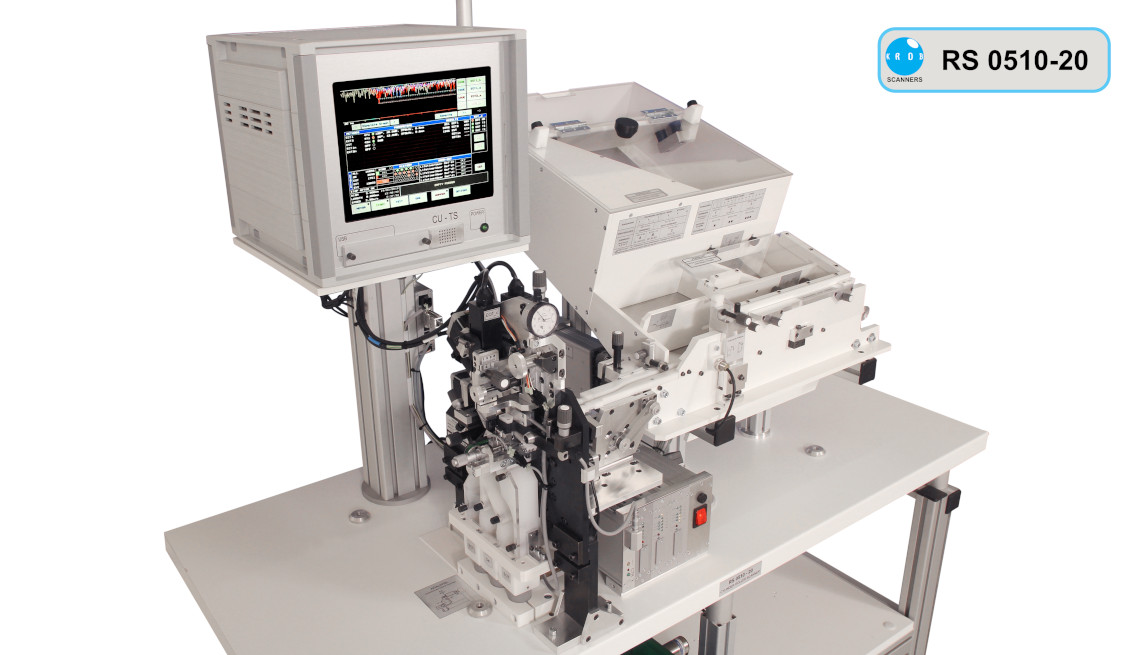

Roller Scanner – for dry inspection of surface and sub-surface of casings and surface of faces of steel rollers

The Roller Scanner is an automated sorting machine for defectometric inspection of surface and sub-surface of the casings and surface and sub-surface of the faces of clean and dry steel rollers. The rollers are inspected using an eddy-current (ECT tester), optically using a laser beam (EOT tester) and a vibrational integrated accelerometer (EVT tester)

We currently offer RS and RS with Hardness Tester for following ranges

Standard equipment of RS machines

- User friendly control using Touch-Screen (CU-TS)

- Immediate evaluation of each roller shown on the screen with an option to print the inspection report

- Inspection methods: optical (EOT), eddy current (ECT), vibration (EVT)

- Hopper for rollers for inspection

- Vibration-free module for orienting and shifting the rollers onto the conveyor belt

- Stepper motors on control elements

- Possibility of monitoring machine operation using WEB BS

- Machine status signalisation

- Storage plates with boxes for inspected and sorted rollers, including sensors monitoring the overfilling of boxes