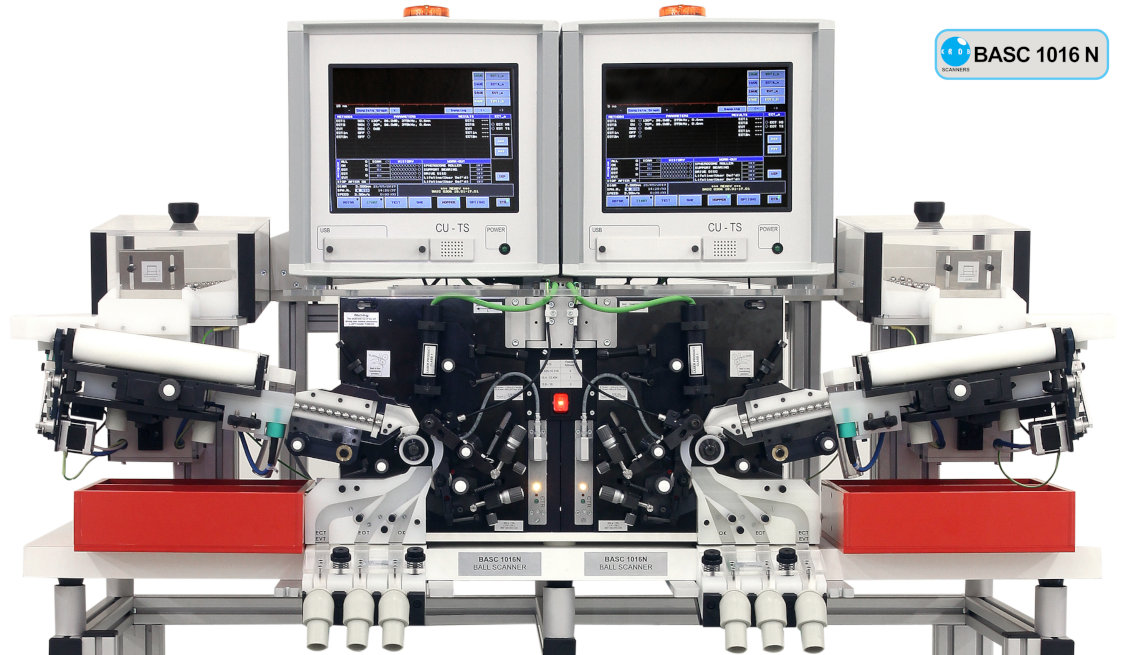

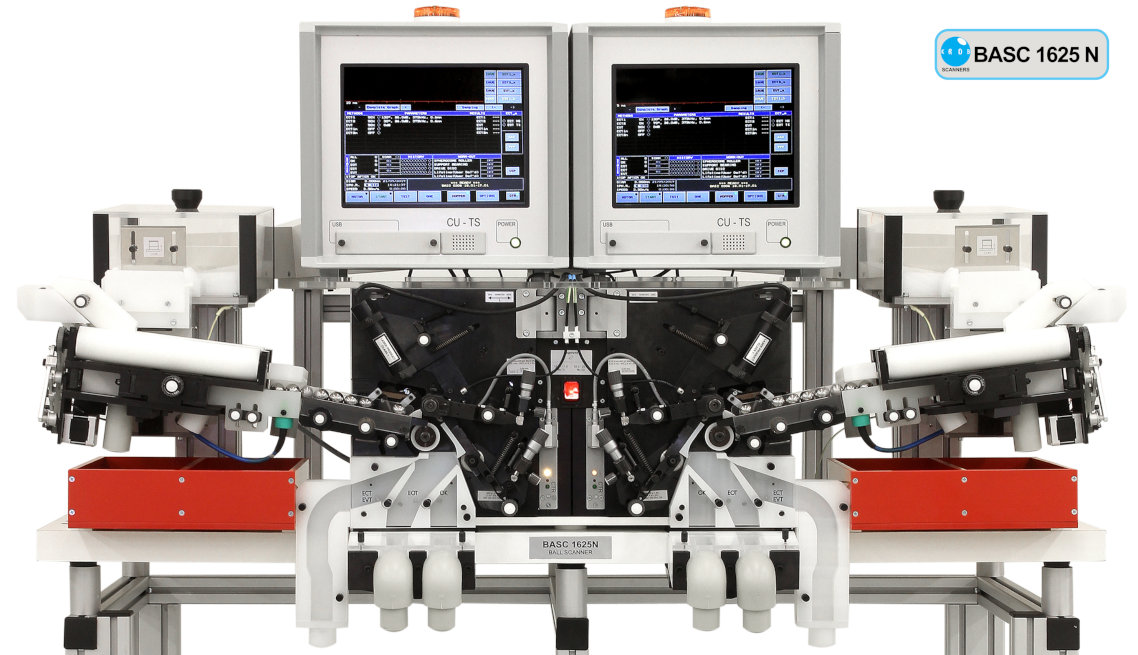

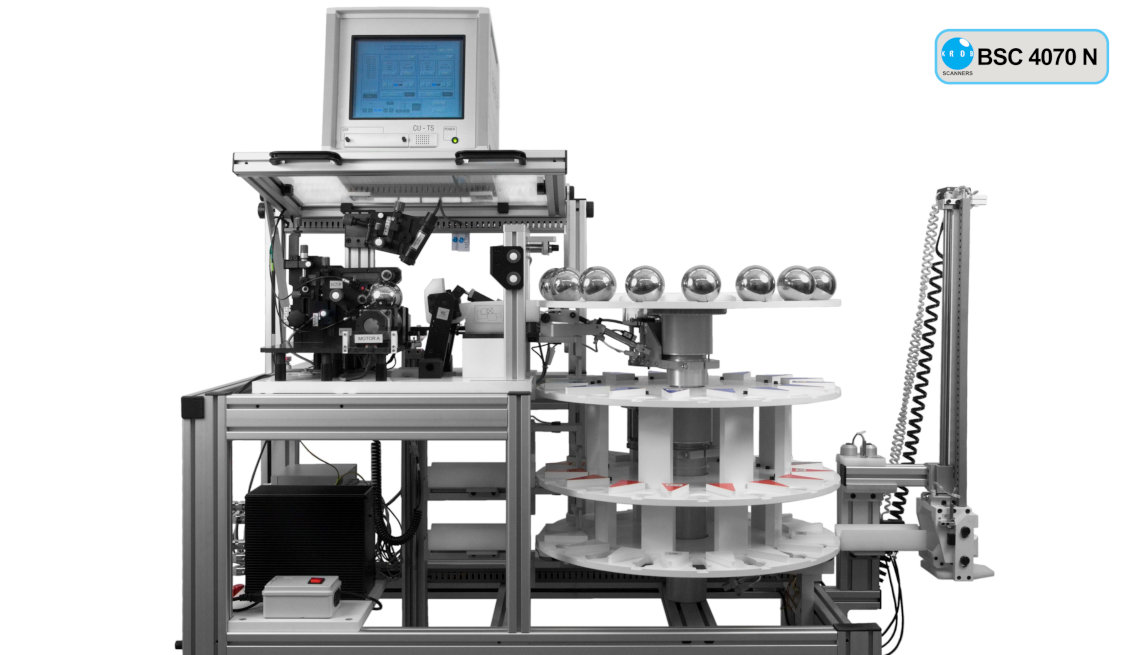

Ball Scanners N – for dry inspection of the surface and sub-surface of dry steel balls

Ball Scanners are sorting machines for non-destructive quality control of the surface and subsurface of steel bearing balls. The inspection is performed by the eddy current method (ECT), the optical laser beam method (EOT) and the vibration integrated accelerometer method (EVT). If another inspection method for quality control is required, please contact the manufacturer.

Since 2015 new line „N“ has replaced the older model range “AS“ and introduces a new line of innovations such as higher precision of key elements due to new motors, greater demand for shock absorbtion on inspected balls, and significantly simplified access to all elements of the machine, all of which which means easier service, new modern design and many more advantages. Thanks to the expression of customer satisfaction one can see that the new „N“ line successfully follows up on more than 25 years of tradition of quality assurance of bearing balls using KROB SCANNERS‘ sorting machines.

Currently we offer N machines in the following ranges

Standard equipment of N series

- User friendly control using Touch-Screen (CU-TS)

- Immediate evaluation of each ball shown on the screen and option to print the inspection report

- Inspection methods: optical (EOT), eddy current (ECT), vibration (EVT)

- Inspection Regimes: STD / AS / WD

- ECT probe types for STD / AS / WD inspection mode

- Selection of speed of the examination

- Hopper for balls

- Pre-sorter of different ball diameter with +/- 0,05 mm precision

- Opening side panel for easier access

- Stepper motors on inspection elements

- Possibility to monitor machine operation using WebBS

- Machine status signalisation